Injection moulding technology

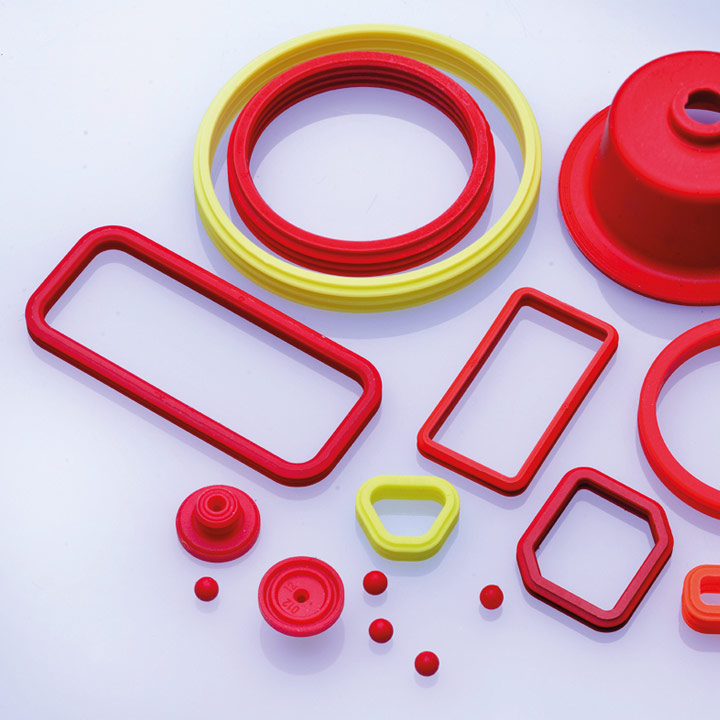

We manufacture moulded parts, damping elements, membranes and moulded seals from all common elastomers with this technology with a focus on liquid silicone rubber (LSR).

Seals and moulded parts:

Special sealing applications require special solutions: We specially manufacture customer-specific seals for the particular requirements of the customer. Modern injection moulding machines are used with the most modern toolmaking technology for production – waste-free, burr-free, no need for reworking. In addition, we offer additional services such as thermal treatment, surface coating and 100% checks.

We describe moulded parts or seals as free-falling if they are produced in medium to large quantities on horizontal injection moulding machines fully automatically. After the tool is opened, these parts are fully automatically ejected from the cavity using push-out or squeeze out devices or other ejector systems. They then fall freely into the transport containers provided. A typical example is the fully-automated production of millions of silicone balls from a tool with 128 cavities.