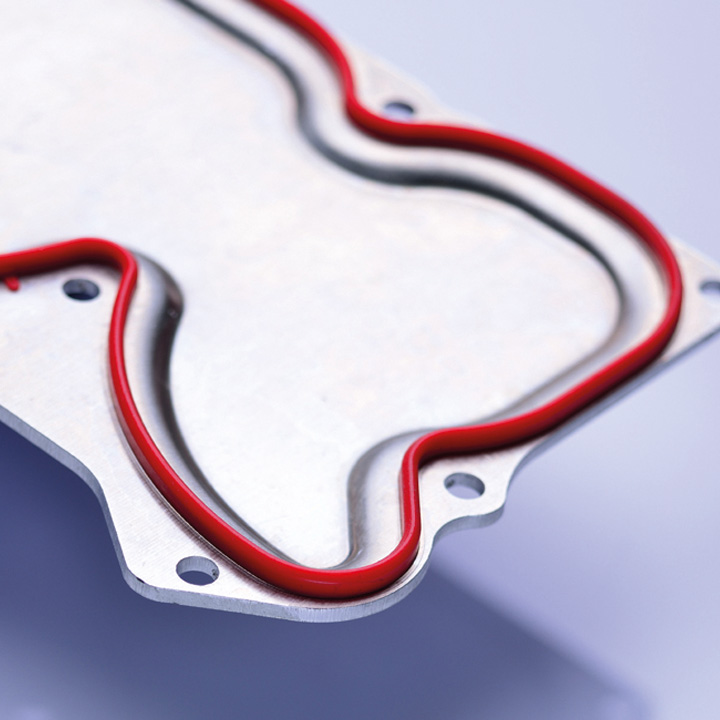

Composite technology

This technology term includes: Rubber plastic composite parts, rubber metal composite parts, silicone plastic composite parts, and silicone metal composite parts. Composite parts consist of a fixed connection between two different components. Normally an elastic material is vulcanised onto a solid substrate.

Suitable metallic substrates are:

- Aluminium, zinc, magnesium die castings

- Aluminium, steel or stainless steel turned parts

- Pressed parts

- Stamped or bent sheets of aluminium, steel, stainless steel, etc.

Suitable plastic substrates are:

- PA

- PPS

- PBT

- PPA

- PEEK

Advantages of the composite technology:

- Best elastomer adhesion to the plastic part

- No additional assembly steps

- Quick cycle times

- Low handling

- High degree of automation

- Stable production processes

- Economical part price

Proper pre-treatment is crucial for a permanently good bond.

We have used all suitable pre-treatment processes in series production for many years. The latest technology is a special pre-treatment for cast parts in series production. This allows demanding tasks for composite parts to be implemented economically.

Composite parts are used in a wide variety of applications in all areas – be it as seals in control units in vehicles, as a damping element in vehicle or aircraft construction or as a shower head for home use.

Composite parts are used in a wide variety of applications in all areas – be it as seals in control units in vehicles, as a damping element in vehicle or aircraft construction or as a shower head for home use.