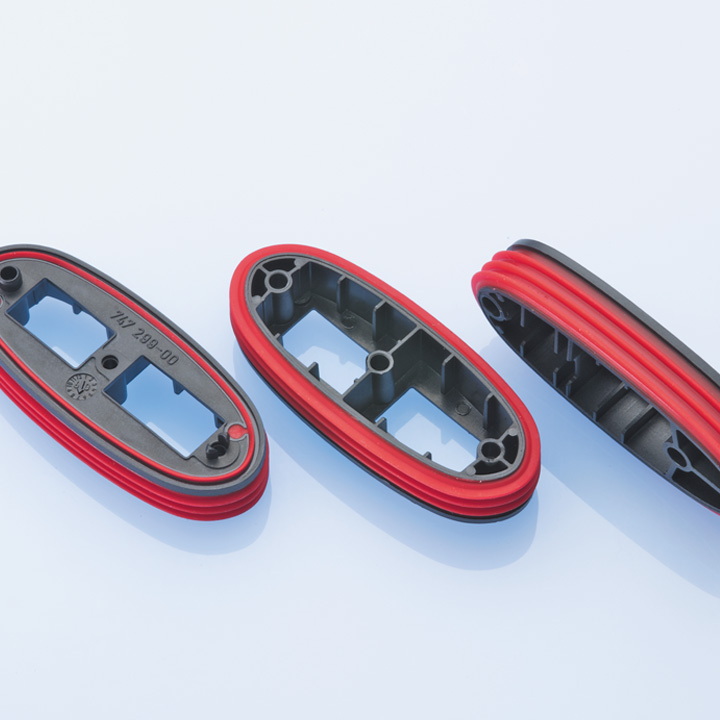

2K injection moulding technology

We have manufactured parts using the 2-component process for over ten years. Here a hard component (thermoplastic) is joined with a soft component (elastomer) in a continuous process to form a composite part. Thanks to the chemical bond between the different materials, excellent adhesion is achieved, without the thermoplastic part requiring chemical pre-treatment. This results in a very efficient and economical process.

The 2-component technology is also ideal for parts with large batches. The method is particularly efficient for the use of liquid silicone rubber (LSR).

Advantages of the 2-component injection moulding technology:

- Best elastomer adhesion to the plastic part

- No additional assembly steps

- Quick cycle times

- Low handling

- High degree of automation

- Stable production processes

- Economical part price