Dosing technology

Be it dosing technology, dispensing technology, free application techniques, freely applied seals, machine dosed liquid gaskets, sealing foams or form-in-place processes (FIP process) – all these terms describe the same thing:

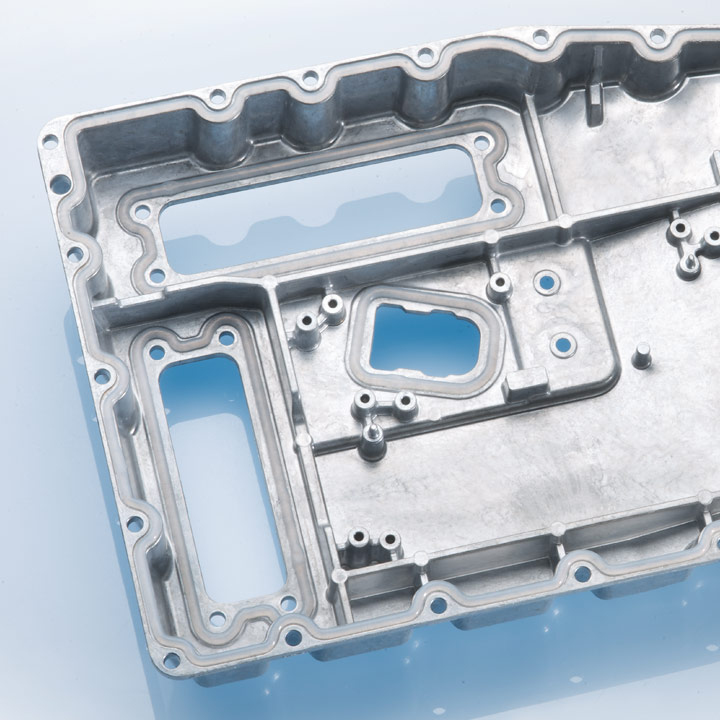

Instead of conventional insert seals, the sealing material (at R.E.T. preferably 1-component or 2-component silicone) is applied by machine in a liquid or paste form with high repetition accuracy directly onto the component.

The direct application of the seal onto the component is done using highly modern 2-D or 3-D dosing systems at high speed and with the latest mixing technology. The dispensing technology presents an interesting alternative to manual seal application as the seals adhere securely to the component.

Advantages of the dosing technology:

- Quick, economical implementation

- Small to large components

- Small to large batches

- Seal application onto different levels in a single clamping process

- Good adhesion between elastomer and carrier component

- High process reliability